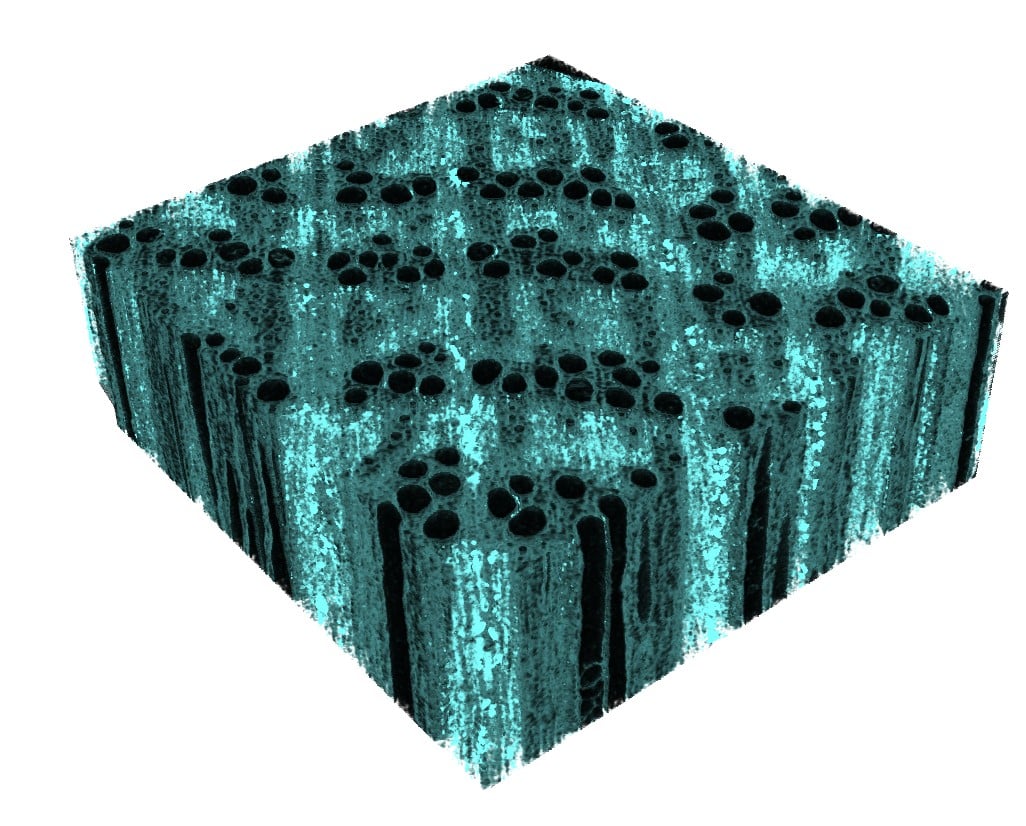

(Conceptual image generated by © Thanawin - stock.adobe.com)

In a nutshell

- Scientists created stronger wood by infusing oak with iron minerals at the cellular level, increasing stiffness by 260% and hardness by 127%

- While dramatically stronger at microscopic scales, the treated wood showed minimal improvement in overall strength when tested as larger pieces

- This technology could eventually lead to more sustainable building materials by enhancing wood’s natural properties with minimal environmental impact

BOCA RATON, Fla. — Researchers have figured out how to make wood much stronger by injecting it with iron minerals found in soil. This discovery, while still experimental, might eventually transform how we build everything from furniture to skyscrapers.

A research team from Florida Atlantic University recently took regular oak and infused it with ferrihydrite — a mineral commonly found in dirt — boosting the wood’s cellular stiffness by more than 260%. Their work, just published in ACS Applied Materials & Interfaces, shows how biological materials like wood can be dramatically strengthened while maintaining their natural benefits.

How Scientists Created ‘Super Wood’

Wood has always been prized for its favorable strength-to-weight ratio, but it’s typically no match for steel or concrete in large-scale construction. This innovation could change that equation dramatically by enhancing wood’s inherent properties at the smallest scale possible – the cellular level.

Unlike traditional wood treatments that just coat the surface, this approach incorporates iron minerals directly inside the microscopic structure of the wood. It’s similar to how some sea creatures like limpets and chitons naturally incorporate iron minerals to create extraordinarily hard teeth.

The team used a chemical process. First they soaked oak in ferric nitrate, then added potassium hydroxide to create tiny iron mineral particles within the wood’s cell walls. When they tested the treated wood using advanced equipment, they found substantial improvements in hardness and rigidity at microscopic scales.

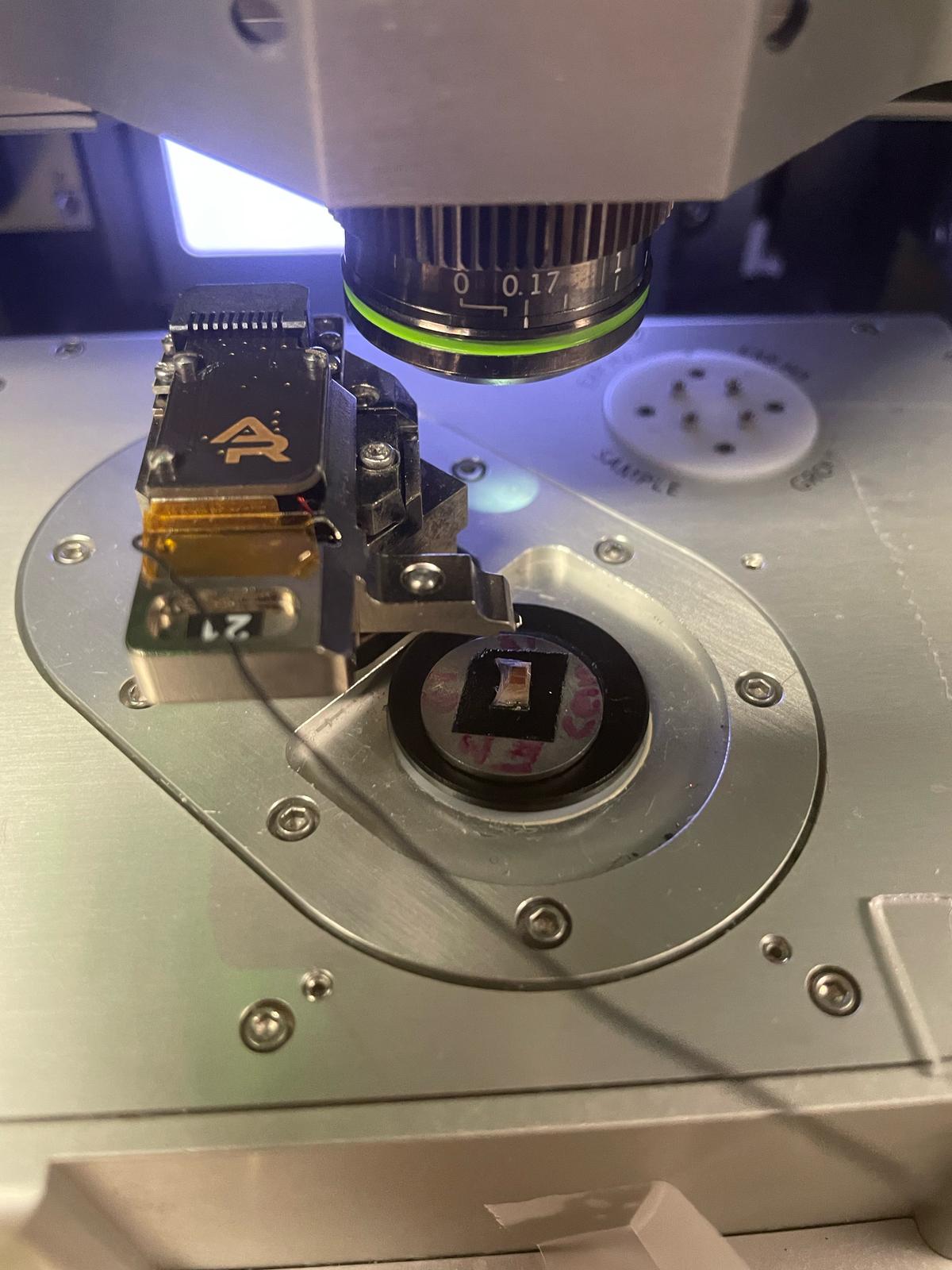

To measure these changes, the scientists employed sophisticated techniques including nanoindentation inside a scanning electron microscope and bimodal atomic force microscopy. These methods allowed them to map exactly how the treatment affected different components of the wood’s cellular structure.

Most importantly, the minerals penetrated deep into the wood’s secondary cell walls — the parts that provide structural strength. This integration created a natural composite with enhanced properties.

The catch? Even with these impressive gains at the cellular level, when researchers tested larger pieces of the treated wood, they didn’t see significant improvements in overall strength. Researchers explain that the harsh chemical conditions used during mineralization — including extended exposure to highly acidic ferric nitrate — likely weakened the natural adhesion between wood cells, a critical factor for macroscopic strength.

Additionally, the chemical treatment may have degraded some of the wood’s natural polymers, further compromising its structural integrity. Residual salts from the treatment process could also have increased the wood’s moisture content, a well-known factor that negatively affects wood’s mechanical performance. Together, these effects likely offset the gains achieved at the cellular level during large-scale mechanical testing.

Building a More Sustainable Future

As construction firms seek alternatives to carbon-heavy materials like concrete and steel, enhanced wood products could offer environmental benefits while maintaining necessary strength.

Combining available minerals like ferrihydrite with renewable wood creates a promising direction for next-generation building materials that preserve wood’s environmental advantages while improving its performance.

“This research marks a significant advancement in sustainable materials science and a meaningful stride toward eco-friendly construction and design,” says Stella Batalama, the dean of FAU’s College of Engineering and Computer Science. “By reinforcing natural wood through environmentally conscious and cost-effective methods, our researchers are laying the groundwork for a new generation of bio-based materials that have the potential to replace traditional materials like steel and concrete in structural applications.

“The impact of this work reaches far beyond the field of engineering,” she continues. “It contributes to global efforts to reduce carbon emissions, cut down on waste, and embrace sustainable, nature-inspired solutions for everything from buildings to large-scale infrastructure.”

While this mineral-reinforced wood isn’t ready for commercial use yet, it points toward a future where our buildings might be constructed primarily from trees rather than quarries or mines — returning to natural materials, but with significantly improved strength.

Paper Summary

Methodology

Researchers used American Red Oak (Quercus rubra) as their base material and developed a chemical process to incorporate ferrihydrite (a form of iron oxyhydroxide mineral) into the wood’s cell walls. They accomplished this by first immersing 5mm wood cubes in a 0.2M solution of ferric nitrate for 24 hours using vacuum-impregnation. Then they added potassium hydroxide solution until reaching a pH of 7-8, followed by another vacuum impregnation step. After 24 hours, samples were thoroughly washed and air-dried. To characterize the mechanical properties of both treated and untreated wood, they employed three different techniques: nanoindentation inside a scanning electron microscope (SEM), bimodal amplitude modulation frequency modulation atomic force microscopy (AM-FM AFM), and conventional three-point flexural testing on larger samples.

Results

The research demonstrated remarkable improvements in the mechanical properties at the cell wall level. SEM nanoindentation showed the Young’s modulus (a measure of stiffness) increased by 260.5% in the treated wood compared to untreated samples, while hardness increased by 127%. The AM-FM atomic force microscopy confirmed these findings, showing a 314% increase in average Young’s modulus across the cellular structure. The treated wood also demonstrated nearly twice the plastic deformation energy, which could contribute to damage tolerance. Despite these microscale improvements, three-point flexural tests on larger wood samples showed only a modest 10.24% increase in flexural stiffness, and the difference was not statistically significant. The fracture patterns in both treated and untreated samples were similar.

Limitations

The researchers identified several limitations in their approach. The harsh chemical conditions during treatment might have weakened cell-cell adhesion, potentially explaining why the microscale improvements didn’t translate to significant macroscale strength enhancements. They also noted that their region-specific mechanical testing focused primarily on fiber cells that provide mechanical support, but didn’t examine other anatomical regions like vessels, pits, or parenchyma cells that could influence overall mechanical behavior. Additionally, residual salts from the treatment might have affected moisture content, which is known to impact wood’s mechanical performance.

Funding and Disclosures

The research was supported by several grants and fellowships, including a Department of Energy (DOE) Office of Science Graduate Student Research fellowship for one author, National Science Foundation funding (NSF2137663, Division of Materials Research), and a SMART Scholarship funded by OUSD/R&E (The Under Secretary of Defense-Research and Engineering). Advanced atomic force microscopy studies were conducted at the Center for Nanophase Materials Sciences, a U.S. Department of Energy User Facility at Oak Ridge National Laboratory.

Publication Information

The paper titled “Multiscale Mechanical Characterization of Mineral-Reinforced Wood Cell Walls” was authored by Steven A. Soini, Inam Lalani, Matthew L. Maron, David Gonzalez, Hassan Mahfuz, Neus Domingo-Marimon, and Vivian Merk. It was published in ACS Applied Materials & Interfaces (volume 17, pages 18887-18896) on March 12, 2025. The paper was initially received on January 2, 2025, revised on February 28, 2025, and accepted on March 4, 2025.